Development Milestones

- 43+ years of collective experience in designing and developing power transmission devices and gear systems

- Development of power pesticide sprayers, seeders, and tractor transmissions

- Development of 1-ton fork shift and axle parts for Hyundai Motor Company

- Development of Korea’s first Hemming Machine

- Development of Hyundai Heavy Industries Power Transmission, electric work vehicles, e-wheelchairs, and agricultural machinery

- Development of general industrial machinery

- Development of power transmissions for electric vehicles with patent registrations

List of Patents Owned

- Gear orifice system with free zone

- Viscosity damper in elliptical housing with planetary gear systems for emergency escape stairs

- Drive unit of the electric switch gear

- Power transmission of an electric vehicle

- Reducer systems

- Compound planetary gear system of the No-Back-Device

- Limit-powertrain of the dual-axis electric switch gear

- Differential gear and reduction gear installation structure for electric vehicles

- Automatic opening and closing device for a greenhouse with ball ramp brake

- Automatic opening and closing device of positive and negative rotation type with ball ramp brake

- Powertrain housing installation structure for electric vehicle

- Active two-stage reduction device

- 2-stage variable speed rotary transmission device

- Planetary gear system

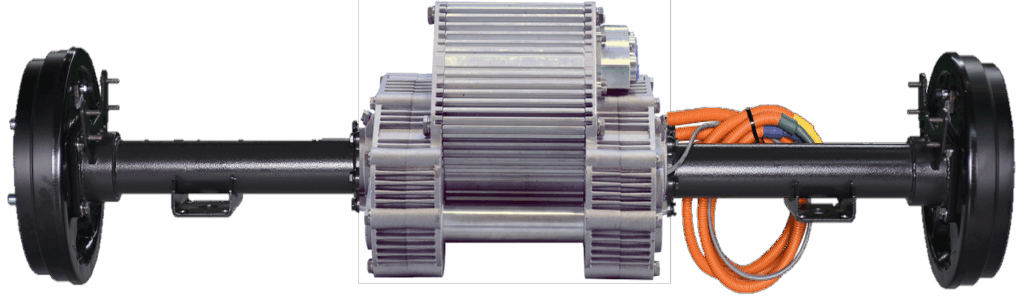

- Trans axle for electric vehicles equiped with hollow-shaft type motor

- Reduction device to prevent rotational backflow

- Limit adjust device using planetary gear

- Intergrated accelerator viscous fluid damper for emergency escape stair

- Free fall control using viscous fluid and mechanical self-locking reducer for emergency escape stair

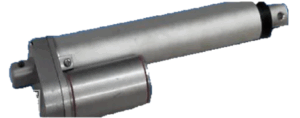

- 2-stage variable electric actuator

- One-way or two-way No-Back-System

- Air balance hoist

- Cycloid reducer

Power transmission systems for EVs

Features- The only patented product globally

- Functions quietly and reliably, thanks to the planetary reducer

- Exceptional durability

- Quickly adapts to variations in motor output and gear reduction ratio

- Ideal for maintaining vehicle weight balance with a symmetrical design on either side

- Motor output range: 5 kW ~ 15 kW

- Reduction ratio application range: 1/5 ~ 1/15

- Applicable electric vehicles: 3-wheel, 4-wheel type cargo and passenger vehicles, E-rickshaw

- Track type moving device: Agricultural track car, and industrial track car

- Special-purpose electric vehicles: Vacuum cleaner robot, Golf Car, and Leisure vehicle

Pre-assembly product image

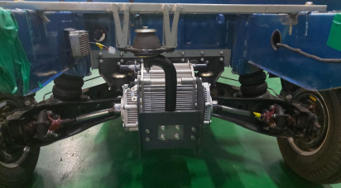

Onboard view of the powertrain assembly to a 3-wheeler EV

Frontal image after assembly work as a powertrain is done

Automatic 2-Speed Transmission: 2-speed variable reducer development project

Field of Application- Electric Actuator

- Automatic Switch for Variable Power

- Electric Work Vehicle

- Power Lift

- Industries or fields where productivity enhancement and energy efficiency are simultaneously imperative

Mechanical No-Slip Systems

Field of Application- Winch

- Automatic Opener for Smart Farm

- Step Mill

- One-way and two-way gravity anti-slip device

- Anti-slip devices for electric commercial vehicles, designed for a single wheel.